Cocktail Shaker from Hermann Goering's Personal Service "Reichswerke Hermann Göring-Wellner", circa 1937

Hermann Goering's Personal Service Cocktail Shaker on which the Feldmarschall's "Coat of Arms" is present in relief.

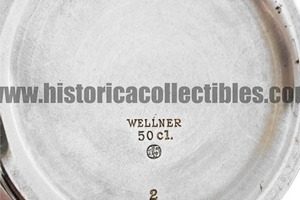

The Shaker was part of one of Hermann Goering's personal service and was created by the Conglomerate Industries "Reichswerke Hermann Göring" of Berlin (active only from 1937 to 1945) in collaboration with "Karl August Wellner" of Aue in Saxony, a company specialized in silver plating of nickel silver cutlery and crockery. Both "Reichswerke Hermann Göring" and "Karl August Wellner" were also suppliers of tableware to Adolf Hitler and the Reich Chancellery in Berlin.

Furthermore, the "Wellner" mark is accompanied by a numerical stamp which indicates the weight of silver used for plating.

The Shaker is complete and in excellent conservative condition.

Reichswerke Hermann Göring, was an industrial conglomerate of Nazi Germany. It was established in July 1937 to extract and process domestic iron ore from Salzgitter which was considered uneconomic by private steel mills. The state-owned Reichswerke was seen as a vehicle to accelerate the growth of ore mining and steel production, regardless of the plans and opinions of private capitalists, which went against Adolf Hitler's strategic vision. In November 1937 Hermann Göring gained uncontrolled access to state funding and launched a chain of mergers, diversifying into military industries with the absorption of Rheinmetall. Göring himself oversaw the Reichswerke but did not own it in any sense and did not directly profit from it, although he sometimes withdrew money for personal expenses.

After the Anschluss, the Reichswerke absorbed Austrian heavy industries, including those owned by private German investors. The group of steelworks and supporting companies in Linz became its most important asset. The Nazi leadership regarded the acquired assets as state property and was unwilling to share the spoils with German businesses. After the German occupation of Czechoslovakia, the Reichswerke absorbed between 50 and 60 percent of Czech heavy industries. The pattern was repeated in occupied Poland, France and the Soviet Union.

The Reichswerke operated captured assets far from its base such as Liepāja in Latvia and Donetsk in eastern Ukraine. It provided an eighth of Germany's steel production during World War II and created a Nazi-controlled military complex that was independent of private interests.

By the end of 1941 the Reichswerke became the largest company in Europe and probably in the whole world, with a capital of 2.4 billion German marks and around half a million workers.

In 1942 the inefficient structure was reduced in size. Its arms and ammunition resources were integrated into the Ministry of Armaments; the Reichswerke's mining and steel core continued to operate under Göring's supervision until the end of the war, albeit at a loss. The conglomerate was broken up by the Allies in 1944–1945, but the Salzgitter plant continued to operate as the Reichswerke until 1953. The Reichswerke logo, which resembled Göring's coat of arms, remained in use until the mid-1980s.

August Wellner & Sons, was one of the largest German manufacturers of hotel cutlery and crockery dating back to the imperial era. Its products were famous all over the world for their high quality and beautiful styles. By 1911, the August Wellner & Sons factory became one of the largest silver plating companies in the world.

By 1913 the company employed 5,000 people and produced 36 million pieces of cutlery each year. The company has supplied numerous European luxury hotels, including the Grand Hotel on the Lido of Venice, the Baur au Lac in Zurich, the Kempinski Hotel in Berlin, the Kurhaus in Davos, the Maloja Palace Hotel in St. Moritz, to name just a few some.

Large passenger ships such as Titanic (UK), Imperator (Germany), Saturnia and Vulcania (Italy), used Wellner cutlery in their restaurants.

The famous August Wellner metalworks factory was founded by August Wellner's father, Christian Gottlieb Wellner, in the small town of Aue (Saxony, Germany), located in the wooded hills of the Erzgebirge (Erzgebirge Mountains). In this area of Germany, a tin smelter was established in Aue (meaning "floodplain") in 1663, and remained in operation until 1803.

Fifty years after closing, the factory buildings were used as a starting point for the manufacture of August Wellner's metal objects. However, before this occurred, an important invention was made in the nearby town of Schneeberg ("snow mountain"). In 1823, the German chemist Dr. Ernst August Geitner (1783-1852) developed a new alloy, very similar in appearance to silver, but significantly cheaper. Therefore, he called this league "Argentine". It consisted of 20% nickel, 55% copper and 25% zinc. Later, in 1829, Dr. Geitner established his silversmith foundry in the suburb of Aue.

The new alloy that imitated silver soon became very popular. The Henninger Brothers (Gebruder Henninger) foundry in Berlin proposed a similar alloy (5-30% nickel, 45-70% copper and 8-45% zinc with traces of lead, tin and iron) in 1854, it was called "Neusilber". Subsequently, both the Argentana and the Neusilber were used in Germany and Austria-Hungary under the trade name of Alpacca which corresponds to the name of the animal that grazes in the South American Andes of Chile, Bolivia and Peru.

Since this new alloy looked quite similar to pure silver, some people had the idea of using it as a base metal to plate future cutlery and tableware with a thin layer of silver. This silvering could be done by different methods, but high-voltage electrical deposition enjoyed wide application. In this way, two objectives were immediately achieved: 1) the cost of the final silvered product was reduced by at least 5-7 times due to the much lower amount of silver used for plating; 2) the appearance of the objects was as perfect as that of silver and did not change significantly as the silver layer wore.

August Wellner & Sons also pioneered the standardization of silver content in its silver flatware products. Before 1911 the following standards for silver content were introduced:

1) WS grade or “Wellner Silber” (Wellner Silver), the highest quality standard, which corresponds to 100 grams of silver used for plating two dozen pieces of cutlery;

2) ES grade or "Extra Stark versilbert" (extra strong silver plating), which corresponds to 90 grams of silver used for the plating of two dozen pieces of cutlery;

3) I degree (First degree), which corresponds to 60 grams of silver used for the plating of two dozen pieces of cutlery;

4) II degree (Second degree), which corresponds to 48 grams of silver used for the plating of two dozen pieces of cutlery;

5) Pure nickel silver, which means no silver has been used for plating.

The most expensive was "Wellner Silver", advertised by the factory as "a perfect substitute for genuine silver" with a 20-year warranty. Secondly, in 1910 a dozen pieces of silver cutlery made by August Wellner & Sons and covered with WS quality plating cost 32 marks. At the same time, the same amount of plated cutlery with ES grade coating costs 30 marks, with grade I coating 26 marks, with grade II coating 22.80 marks, and a dozen pure (uncoated) alpaca cutlery costs only 11 marks.